ARTICLE

1

Comparative Analysis - The US M9 Series And Its Copies

| _____In

the later years of W.W.II, it became of importance

that the US Chemical Warfare Service develop a lightweight

gas mask for paratroopers and amphibious assault troops.

The British had already developed such a mask called

the Mk. I Light Anti-Gas Respirator (below left). Instead

of attaching the filter canister to the face piece

via a corrugated rubber hose, the Mk. I used a round

filter with a large opening that was screwed into the

left side of the face piece. This innovation enhanced

head mobility and also eliminated other problems with

dexterity caused by heavy filter canisters that were

worn around the chest or at the side. Breathing resistance

was also lowered because the soldier did not have to

draw air up through a heavy corrugated rubber tube,

as with most other W.W.II service gas masks. It is

likely that the British Mk. I was the inspiration for

the US M5-11-7 Assault Service Gas Mask (below center),

which was introduced in late 1943. The M5-11-7 went

on to be carried by US troops during the famous D-day

assault on Normandy, making it a significant W.W.II

collectable. The Assault Gas Mask was nothing more

than a altered US Army M3 Lightweight Service Gas Mask.

The chin area of the mask that usually had a hose attached

was sealed off and a 60mm filter inlet was integrated

into the left side of the neoprene face piece. A fabric

neck strap was also added to the head harness to keep

the face piece straight, as the mask had a tendency

to shift on the wearer's head due to the extra weight

on the left side. Despite the effort to create a serviceable

lightweight combat mask, the M5-11-7 was made of neoprene

rubber, and the face blank was prone to a stiffening

effect known as "cold

set". After the war, the C.W.S. set out to design

a better lightweight mask that did not have the problems found

with the M5-11-7. In the late 1940s, the E48 mask (below

right) was developed. The E48 was an early prototype of

the US M9 Field Protective Mask which was standardized

in 1947. There were a few early production M9s made from black rubber like the E48 (below left, 2nd row). However, the bulk of all standardized M9s produced were made entirely from natural gray-green rubber with a black rubber oronasal cup fitted on the inside to aid the demisting process. |

THE BRITISH MK. I LIGHT

ANTI-GAS RESPIRATOR |

THE US M5-11-7 ASSAULT

SERVICE GAS MASK |

THE US ARMY E48 MASK |

| _____The

M9 was manufactured with a filter inlet on both the left

side (below center) and on the right side (below right) which

enabled either left or right handed weapon sighting. |

AN EARLY PRODUCTION M9 |

THE US M9 FIELD PROTECTIVE MASK |

THE US M9A1

(RIGHT SIDE FILTER INLET) |

|

ABOVE: A US Marine ABC (Atomic/Biological/Chemical) team trains in Hawaii wearing M9 gas masks (July 1959). |

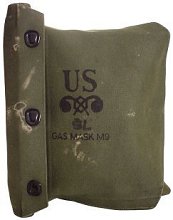

| _____The

M9's original carrier was an upgraded version of the earlier

M7 carrier (below left) which was issued with the M5-11-7

Assault Service Gas Mask. The M7 carrier was made of a rubberized

duck materiel that could be rolled and snapped shut to make

it water tight. The M9's carrier, designated the C15R1 used

the same water proofing concept but was made of an olive

drab duck materiel coated with rubber on the inside. Sometime

around 1950, the M9 was upgraded to the M9A1 after a new

carrier was introduced, designated the M11 carrier (below

right). The mask itself did not undergo any changes. |

THE M7 CARRIER |

THE C15R1 CARRIER

|

THE M11 CARRIER

|

|

|

|

The M9 fitted with the M-4 Toxicological Protective Hood |

THE US ABC-M21 ROCKET PROPELLANT GAS MASK |

THE US M15 COMPRESSED AIR BREATHING APPARATUS |

| _____The

M9 series mask came in three sizes: small, medium and large

and proved to be a very comfortable mask that offered a

high level of protection. To enhance the mask's protective capabilities, the M-4 Toxicological Protective Gas Mask Hood (above left) could be issued along with the mask. The face piece of the M9 was also

used for the M15 Compressed Air Breathing Apparatus (above

right) and the ABC-M21 Rocket Propellant Gas Mask (above

center). So successful, the M9 design was copied by at least

five countries, possibly more. The closest copies are undoubtedly

the Serbian M-1 and the Korean KM9A1. These masks used a face piece, head harness assembly,

filter and carrier that are virtually identical to the US M9.

There is also the Serbian MC-1 (a

civilian version of the M-1) made without the inner oronasal

cup. Another copy made in Sweden, was also very close in

design. The Skyddsmask-51 used a

dark green rubber face blank and a larger rubber exhale

valve cover, giving it a distinguishable appearance. In

Finland, a slightly modified clone was produced, designated

the m/61. There were several different m/61 variants manufactured, with the earliest type being also virtually identical to the US M9. The last version of the Finnish m/61 was manufactured with a peculiar hard plastic

exhale valve assembly which doubled as a voice-mitter. A

copy of the M9 was also produced by Bulgaria and was made of black rubber giving it an appearance very close to the Korean version. |

THE SERBIAN M-1 |

THE SERBIAN MC-1 |

THE SWEDISH SKYDDSMASK-51 |

THE BULGARIAN M9 COPY |

THE KOREAN KM9A1 |

THE FINNISH M/61 (1st MODEL) |

THE FINNISH M/61 (2nd MODEL) |

THE FINNISH M/61 (FINAL MODEL) |

| _____The US M9 series mask went on to be serviced by the US Army through the Korean War and all the way to the Vietnam era, where it was eventually phased out and replaced by the M17. |

ABOVE: A DIAGRAM OF THE M9 EXPLODED

|

|

|

ABOVE: A diagram illustrating airflow through the M9. |

ABOVE: A photo of an early production M9 as worn. |

REFERENCES USED FOR THIS ARTICLE:

TM 3-205 - THE GAS MASK, MARCH 1951

TM 3-205/T0 14P4-1-31 - PROTECTIVE MASKS AND ACCESSORIES, APRIL 1955

TM 3-522-15 MASK, PROTECTIVE, FIELD, M9 AND MASK, PROTECTIVE, FIELD, M9A1,

OCTOBER 1957

U.S. CHEMICAL AND BIOLOGICAL DEFENSE RESPIRATORS

By Christopher T. Carey

|

|

| |

ABOVE: A worker wearing a protective suit and a M9 gas mask carefully moves some radioactive metal (ca. 1954). |

© NO FUTURE PRODUCTIONS

|

|